Cyber-Physical Manufacturing System

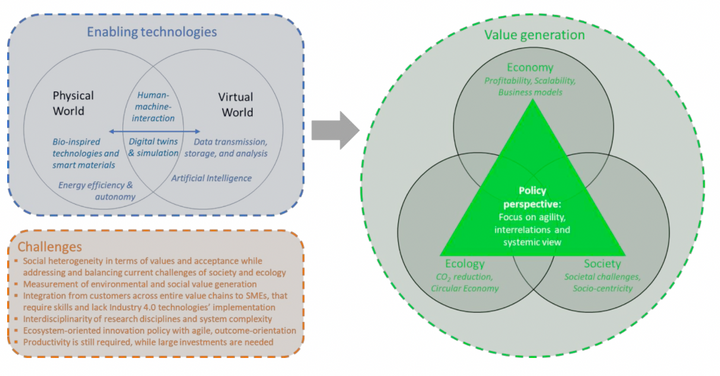

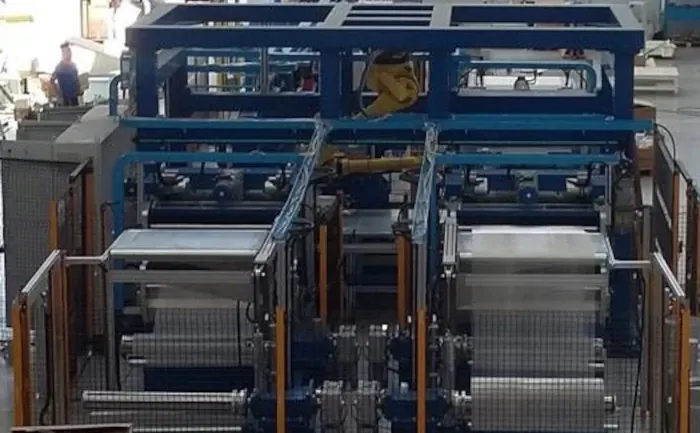

The pillars of Industry 4.0 require a modern smart factory to be integrated, to store data into the Cloud, to access the Cloud for data analytics and to share information at software level for simulation and Hardware-In-the-Loop capabilities. The resulting Cyber-Physical System is often called Cyber-Physical Manufacturing Systems, and it becomes fundamental to cope with increased system complexity and desired performances. However, since a lot of old production systems are based on monolitic architectures, with limited external communication ports and reduced local computational capabilities, it is very difficult to make such production lines compliant to Industry 4.0 pillars. Wireless Sensor Network is a solution for the smart connection of a production line to a Cyber-Physical System architecture, elaborating data through Cloud Computing. The scope of this work, supported by Polytechnic University of Marche, Italy and Syncode Scarl, is to develop a modular software architecture based on OSGi Framework, which is able to seamlessly integrate both hardware and software wireless sensors, to send data into the Cloud for further data analysis and grant both Hardware-In-the-Loop and Cloud Computing capabilities. The Cyber- Physical System architecture has been firstly tested by using Hardware-In-the-Loop tools, then it has been deployed on a real manufacturing line for data collection and analysis over a period of two months.

For more information visit: E-JOURNAL OF THE INTERNATIONAL MEASUREMENT CONFEDERATION - ACTA IMEKO.